Installation & Commissioning Works

Clients

SiemensLocations

Greater Gabbard & Sizewell 132Kv SubstationsEnd User

National Grid

Services Provided

Installation

Site Management

Commissioning

Design

Health & Safety

Project Description

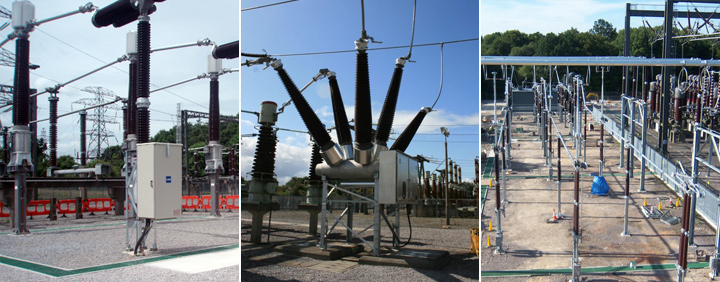

The Greater Gabbard offshore wind power plant is constructed in the sea near Suffolk. The power plant consists of 103 wind turbines each rated with a nominal power of 3.6MW. The scope of work comprises of a complete 132/33kV offshore substation installed on a platform at Gabbard equipped with three 180MVA three winding transformers called GT1, GT2 & GT3. Each of these transformers will transport power to the onshore Leiston substation through submarine cables.

The Greater Gabbard onshore substation will connect the power export cable from the wind farm to the transmission network. This substation will be located within existing plantation woodland 700m from the coastline of Sizewell, in Suffolk. The substation will comprise two compounds. The NGET compound will be called Leiston substation and consists of 14 bay of 132kV Gas Insulated Switchgear. In addition to NGET owned breakers this substation will also have GGOWL owned three circuit breakers to connect wind farm export circuit. The GGOWL owned compounds will have 132kV GIS switchgear, Reactive compensation transformer and 13.9 kV switchgear. 132kV switchgear will have three bays for reactive transformer, export feeder from the wind farm and connection to the NGET feeder.

The total length of the export cable from offshore substation up to the onshore station is about 45 km for both export circuits.

All plant and equipment shall be protected via suitable protection equipment to prevent damage and allow disconnection in the event of faults or transients. The type of faults shall include short circuits, ground faults, asymmetric voltages or currents, temporary or transient over-voltages, switching surges and lightning surges. In addition protection against abnormal supply system variations in frequency, voltage and out of balance shall be provided.

Project Highlights

Commissioning on Module 3 at Greater Gabbard Onshore Substation has now been completed. As of 22nd April, no turbines are installed to date and the submerged sea cables to the offshore substation are about to be jointed at the beach at Sizewell. This means in order to energise the equipment to ensure it meets Grid code compliance and to meet contractual obligations, it needs to be energised from a new 132kV substation which connects into Sizewell 132kV Substation. There have been a number of delays in achieving energisation due to GIS equipment flashing over during initial switching programme by National Grid.

The National Grid Substation was energised on 1st April; this was followed by a week of monitoring to establish harmonic frequency levels in the system.

Module 3 switching programme was started on 12th April and involved energisation of 132kV HIS (Highly Integrated Switchgear), 132/13.9kV Transformer, 132kV Harmonic Filter, 13.9kV Switchboard and an SVC+, all went well with no major problems. Week beginning 19th April, the 13.9kV MSC and MSR where energised which commenced without incident, monitoring and testing the performance of the SVC+ is undergoing. Specialist Siemens engineers are carrying out all SVC+ testing.

The 13.9kV/415v Auxilliary Transformer and AVR (Automatic Voltage Regulator) remain to switch in is scheduled to happen week beginning 26th April.

SES have had 3 commissioning engineers on the Greater Gabbard site from August 2009 to Jan 2010, Currently 2 SES commissioning engineers are on site and work will continue on the other two modules until late summer 2010. This is one of the first Substations of its type to manage offshore wind power generation using relatively new Siemens Compensation equipment, providing different challenges to the commissioning engineers than on traditional schemes of commissioning done to date by SES.

Client Feedback

"The SES team where very pro active to the unexpected site project challenges and managed to energise the project stages in a professional manor"

Barry Turnbull - Fluor Limited